焦煤预处理

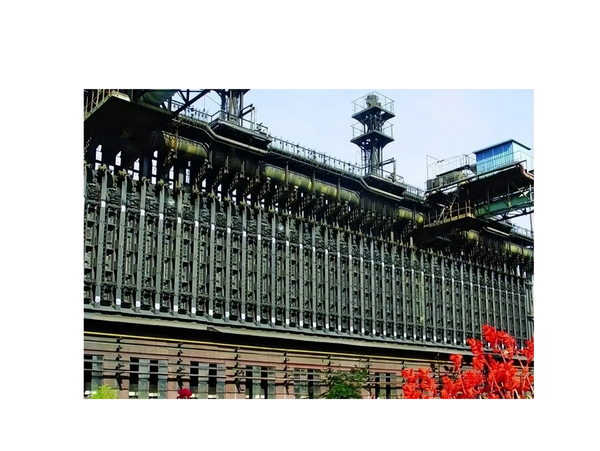

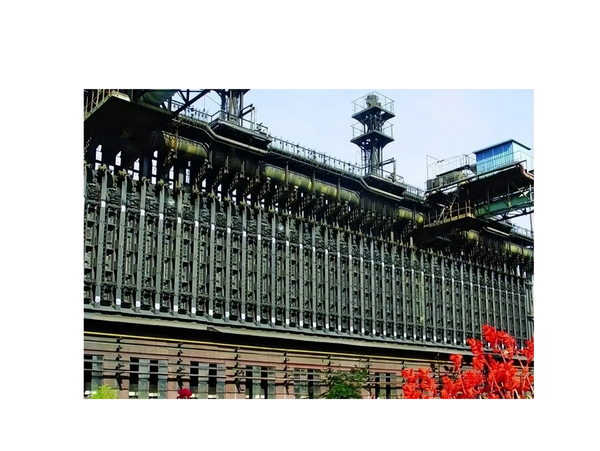

戴尔塔焦煤预处理工艺基于其独有的高温流化床干燥技术,并借鉴新日铁的经验和教训而开发的领先于新日铁的焦煤预处理工艺。

戴尔塔焦煤预处理工艺仅对炼焦过程中易产生粉尘的超细煤进行造粒,将需要造粒的超细煤比例降低至焦煤总量的10%;超细煤造粒工艺采用水溶性粘结剂或无粘结剂造粒工艺;焦煤预热温度不超过220℃,预热后的焦煤运输和储存仍可利用现有的焦化厂设备(皮带输送机、煤塔和装料车),而无需采用密相气力输送。

请下载底部的附件

Coking Coal Pretreatment

The development of Delta coking coal pretreatment process is based on Delta's proprietary high-temperature fluidized bed drying technology and draws on Nippon Steel's experience.

Delta process only briquet the ultra-fine coal (about 10% of the coking coal amount) that is prone to cause dust problems during the charging process; ultrafine coal briquetting can be water-soluble binders or binderless,

Please download attached file at the bottom

低阶煤热解

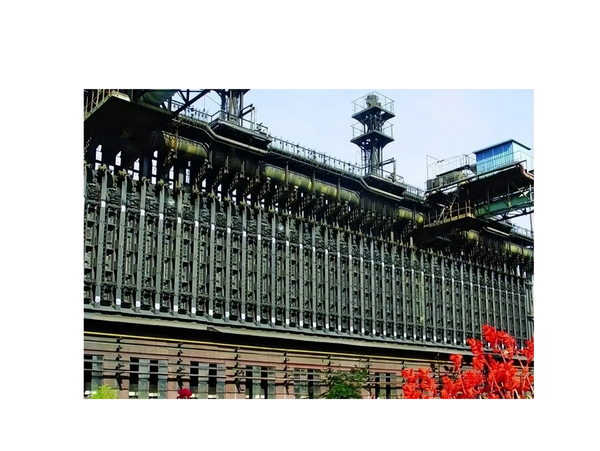

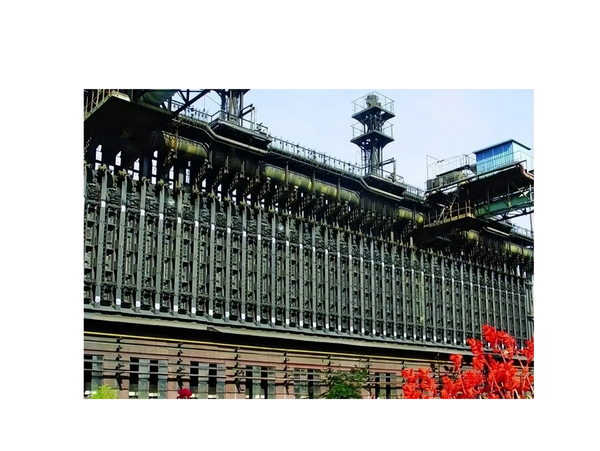

低阶煤热解将低阶煤通过干燥、预热和热解转化为三种形态(三种品质):气体(热解气)、液体(煤焦油)和固体(半焦)。热解气、煤焦油和半焦进一步转化为油、气、电、热能和有机化工产品。

戴尔塔低阶煤热解工艺基于戴尔塔独特的高温流化床干燥技术及其在间接热交换褐煤垂直移动床干燥机领域的经验而开发。该工艺具有以下优势:热解气中粉尘含量极低(煤焦油品质最佳);精确控制热解温度,最大程度提高煤焦油产量;单套装置产能高;工艺成本和投资低。

请下载底部的附件

Low-Rank Coal Pyrolysis

The LRC pyrolysis process converts low-rank coal into three forms (three qualities) through drying, preheating, and pyrolysis: gas (pyrolysis gas), liquid (coal tar), and solid (semi-coke). Pyrolysis gas, coal tar, and semi-coke are further converted into oil, gas, electricity, heat, and organic chemical products.

The Delta LRC pyrolysis process is developed based on Delta's unique high-temperature fluidized bed drying technology and its experience in indirect heat exchange lignite vertical moving bed dryers. This process offers the following advantages: extremely low dust content in pyrolysis gas (optimal coal tar quality); precisely controlled pyrolysis temperature to maximize coal tar yield; large capacity for sibnfle unit; and low process costs and investment.

Please download attached file at the bottom

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.